Pattern In Casting Introduction

|

| What Is Pattern In Casting |

In the sand casting industry, there is a huge demand for various types of casting based on shape, size, complexity, weight, design, cavities in the pattern and final application in the casting process.

For this purpose, a pattern is employed which can be made from wood, foam, metal, plastic and wax.

I have discussed in detail the article below on patterns in the foundry with diagrams, the difference between mould and pattern, the difference between pattern and casting, the mould cavity made by the pattern and other important topics related to patterns in the casting process.

{tocify} $title={Pattern In Casting Table of Content }

What Is Pattern In The Casting Process?

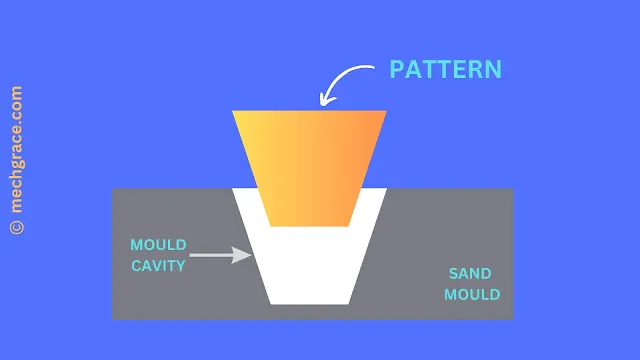

The pattern in the casting process is used to create a mould cavity or impression in the sand to make casting by pouring molten metal into the mould cavity in the sand casting process.

The pattern is a replica of the casting to be produced or manufactured.

The pattern can be defined as a model used for the sand casting process to make a desirable mould cavity.

As shown below in diagram (a) pattern is been taken out of the mould leaving the mould cavity behind.

|

| (a) Pattern In Casting |

The pattern can be also defined as the "principal tool" used during the sand-casting process to make a required mould cavity in the foundry.

The pattern is a model of the object to be cast in the sand-casting process.

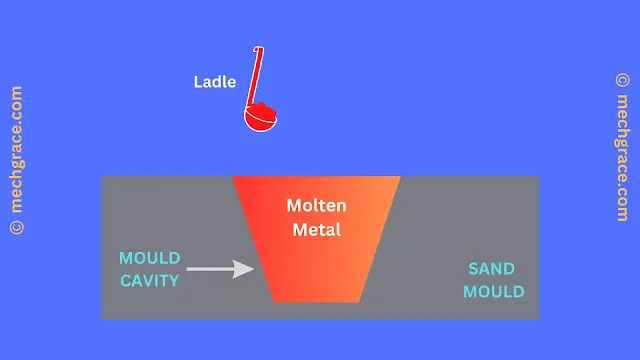

After the pattern is been taken out of the sand mould, molten metal is poured to make the casting of a desired shape which is a replica of the pattern as shown in diagram (b) below.

|

| (b) Molten Metal In The Mould Cavity |

What is the function of a pattern in the casting process?

The main function of the pattern is to make mould cavities in the sand in the sand casting process.

Pattern enables the creation of the core print for supporting the core.

Pattern enables the provision of gating elements such as runners, gates and risers.

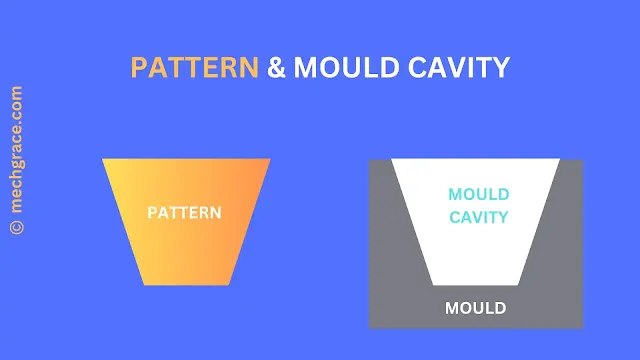

The pattern in the manufacturing process is used to create impressions in the sand to produce a casting of different shapes and sizes as shown below in diagram (c).

|

| (c) Mould Cavity and Casting |

Pattern and Mould

What is the difference between pattern and mould?

The difference between mould and pattern in the sand casting process is shown below in diagram (d).

|

| (d) Difference between Pattern and Mould |

| Pattern | Mould |

|---|---|

| 1) The pattern is a replica of the casting to be produced. | 1) Sand mould is where molten metal is poured into a cavity made by pattern. |

| 2) Pattern is made of wood, foam, wax, metal, plaster of paris and plastic. | 2) Mould in the sand casting process is made of sand. |

| 3) In the sand casting process pattern is used multiple times to produce multiple casting. | 3) In sand casting mould is used just once. |

| 4) The traditional wooden, plastic and metal pattern is not broken after every casting. | 4) The sand mould is broken after every sand casting to take casting out. |

| 5) Pattern is taken out after the cavity in the mould is formed except for the evaporating pattern. | 5) Mould is where final casting is produced. |

| 6) Patterns can be made from various materials such as metals, plastic, evaporating foams and wax. | 6) Mould cannot be made from plastic, wood and foam materials as hot liquid metal is poured in them at higher temperatures to make casting. |

Mould Cavity In Casting

What is mould cavity in casting?

A mould cavity is an impression produced in the sand mould during the mould-making process by a properly designed pattern. This is the impression (cavity) where liquid/molten metal is poured at a higher temperature and allowed to solidify to form sand casting.

The mould cavity is made from the pattern and is in the shape of the final casting.

All mould cavities are made from patterns in sand casting, shell moulding/casting and investment casting. However, not all mould cavities are made from patterns in the sand mould.

Moulds used in die casting are made by machining metal from a metal block and making a mould cavity by electrochemical machining (ECM), electro-discharge machining (EDM), and wire-electric discharge machining (WECM).

Difference Between Pattern And Casting

What is the difference between pattern and casting in the sand casting process?

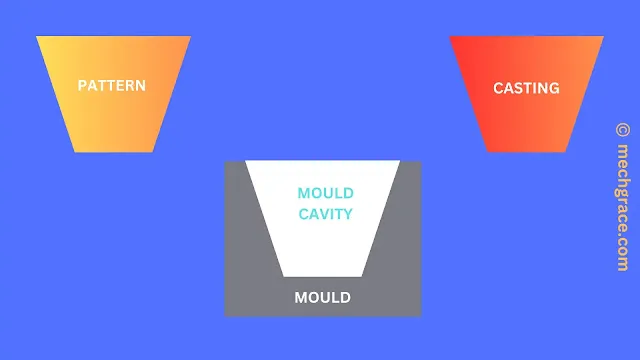

The difference between casting and pattern diagram (e) is shown below

|

| (e) Difference between Pattern and Casting |

| Pattern | Casting |

|---|---|

| 1) The pattern is used to produce mould cavities in the sand. | 1) Casting is a final product ordered by the customer. |

| 2) Pattern is a copy/model of the final sand casting. | 2) Casting is the final product in any casting process. |

| 3) Pattern is withdrawn from the sand mould without breaking mould. | 3) Sand casting is taken out of the mould in the sand mould by breaking the mould. |

| 4) Not all casting processes require pattern example die casting. | 4) Casting is made in a die mould and produced without a pattern. |

| 5) Pattern is a copy/model of the final sand casting. | 5) Casting is the final product in any casting process. |

| 6) The pattern is designed according to the final casting. | 6) Casting is not designed according to the pattern. |

| 7) A pattern can be cast to make another casting and pattern (e.g.: Master pattern). | 7) Casting is not cast to make another pattern. |

How are patterns made?

Patterns are made under carpentry, turning, drilling, milling, grinding, soldering, casting, brazing and welding department.

I have discussed pattern making in casting in detail which explains the pattern-making step-by-step process using various materials such as wood, metal, plastic, plaster of paris and 3D printed pattern.

Pattern is designed according to the design of the final casting.

What is a master pattern in casting?

Wood is the most common pattern used for making mould cavities in the casting process. It is light in weight and cost-effective but comes with disadvantages such as changes in dimensions due to moisture, durability and longevity.

To address this problem "metal patterns" are used to produce mould cavities. In this pattern-making process, instead of using wooden or any other material pattern metal patterns are used to create another metal pattern.

An important allowance called double shrinkage allowance is associated with this pattern considering metal shrinks during the solidification process.

Patterns such as match plate patterns, gated patterns and cope & drag patterns are made using the master pattern in the foundry if the final pattern used in the mould is made from metal material.

How many kinds of patterns are there in the casting process?

There are 17 types of patterns used in the casting process. I have explained types of patterns in casting with diagrams, applications, differences, advantages and disadvantages.

What material is used for making patterns?

Wood, metal, metal alloys, plastic, wax, gypsum and polyurethane foam are used for making patterns in the casting process.

I have written a detailed article on types of pattern material in casting discussing the use, application, advantages and disadvantages of pattern materials.

There are various factors based on which pattern material is selected in the sand casting process.

The properties of pattern material are considered when choosing pattern material.

What is a pattern-making allowance given to the pattern?

The pattern is made with some modifications such as pattern allowance to compensate for the change in the casting dimensions during the casting process, improve the finishing of the final casting, reduce damage to the mould cavity while pattern withdrawal and compensate for shrinkage/expansion of the final casting.

Allowance is an increment or decrement in the dimensions of the pattern to suit the changes in the casting that happen during the sand casting process.

I have explained the types of allowance in casting in types of pattern allowance in the casting article with diagrams.

What colour codes are used for patterns in the sand-casting process?

Multiple colour codes are used on a pattern to make the pattern-making process easy for the pattern maker and during the casting of the products.

This is done so that the pattern maker and casting engineer have a clear idea about the function of every part of the pattern while making mould cavities.

Colour codes also identify core prints and loose pieces of the pattern.

I have discussed these colour codes in the colour coding of patterns in casting in detail.

Pattern In Casting Process MCQ

1) Which of the following options serves the purpose of a pattern in the casting process?

2) In the master pattern the main pattern and casted pattern are made from which material.

3) Which of the following statements are true and related to pattern and mould?

4) Which of the following statements are true and related to pattern and casting?

t serves a visual element and gives an idea about how the final casting will look.

5) Which of the following casting process does not require a pattern?