Cope & Darg Pattern Introduction

Cope and Darg Pattern In Casting

Split-piece patterns can produce castings that are manufactured utilizing both sections of the mould (cope and drag) but there is a limitation over the size of the casting produced.

To solve this problem cope and drag patterns are used to produce casting with larger size.

The mould cavity is made separately for each section of the mould by attaching the pattern to the wooden plate. Only a few large-size casting can be made at a time using this pattern in the sand casting process.

I have written a detailed article below explaining the cope and drag pattern in casting with a diagram, advantages, disadvantages, application and MCQ (Multiple choice questions and answers) related to the cope and drag pattern.

{tocify} $title={Cope and Drag Pattern Table of Content }

Cope and Drag Pattern

What is the cope and drag pattern in casting?

Before we understand the cope and drag pattern it is important to know what is cope and drag in the mould. Cope is the upper section of the mould cavity and drag is the lower section of the mould cavity keeping the parting line as a reference point.

A cope and drag pattern is a pattern used to produce large-size heavy casting by creating a mould cavity separately in the cope and drag side of the mould by attaching the pattern to the wooden plate.

The major difference between the split pattern design and the cope and drag pattern design is that the entire pattern is not assembled together to make a mould cavity as we see in the split pattern.

Only one side of the pattern is used to make a mould cavity on either side of the mould.

The difference between this pattern and the spit piece pattern is that this pattern is attached separately to the horizontal wooden plate but both patterns are not joined together as we see in the split pattern.

The cope side of the pattern is used to make a cavity in the cope section of the mould, while the drag side of the pattern is used to make a cavity in the drag side of the mould. Cavities in the mould are made separately by the pattern.

The pattern is split into two parts as shown in the diagram below (a).

|

| (a) Cope and Drag Pattern |

The cope and drag sides of the pattern are manufactured separately and attached to the flat match plate with alignment pins. Both plates over here are not attached together to make one pattern.

The pattern is then placed in the mould using a moulding machine, and the vibration table and ramming operation take place as shown in diagram (b) below.

When mould is hand made pattern is kept on the bottom board, and sand is poured and rammed with a mechanical wedge to make a mould cavity for casting.

The entire operation is carried out in a flask which serves as a supporting member.

|

| (b) Cope and Drag Pattern In Mould Box |

The pattern is then used to produce a cavity in the sand by taking the pattern out leaving the cope and drag side of the cavity in the mould as shown in diagram (c) below. This same step is repeated to make a cavity on the drag side of the mould.

|

| (c) Mould Cavity After Pattern Been Removed |

Gate, riser and runners are cut after the cope and drag pattern makes the mould cavity in the mould so that molten metal flows from the pouring basin to the mould cavity keeping the runner full during the solidification of the metal.

A mould of the cope and drag side are assembled together to form one mould as shown below in diagram (d)

|

|

(d) Cope and Drag Pattern Mould Cavity |

The molten metal is then poured into this mould cavity created by the cope and drag pattern to make a sand casting as shown in diagram (e) below.

|

| (e) Pouring Operation Cope & Drag Pattern |

Molten metal is then allowed to solidify in the mould cavity to produce casting in the sand casting process as shown in diagram (f) below.

|

| (f) Cope and Drag Pattern Casting |

The cope and drag pattern is a combination of a split piece pattern and match plate pattern with some important differences.

The pattern is split in two like a split piece pattern and is attached on the flat plate-like we have in the match plate pattern but for single and large size casting.

I have explained the difference between cope and drag pattern, split piece pattern and match plate pattern in detail below separately.

What material is used for making cope and drag patterns?

Cope and drag patterns are manufactured using wood. Wood is inexpensive for producing large casting as compared to metal.

Metal such as aluminium and steel are also used depending upon the volume of casting production.

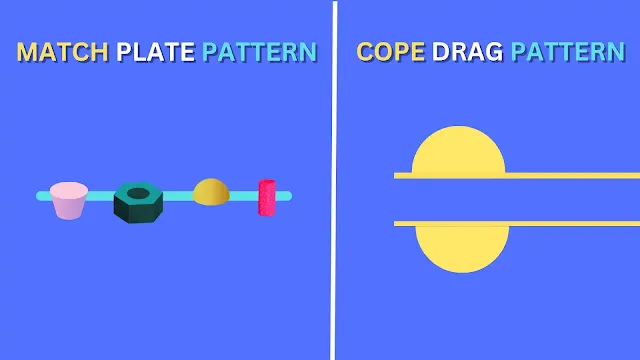

What is the difference between a match plate pattern and a cope and drag pattern in casting?

The difference between the match plate pattern and the cope and drag pattern in sand casting is as follows:

|

| (g) Difference between match plate pattern and cope and drag pattern in casting |

| Match Plate Pattern | Cope and Drag Pattern |

|---|---|

| 1) Match plate pattern produces multiple small-size castings. | 1) Cope and drag pattern produces few large-size casting. |

| 2) A large volume of casting can be produced at the same time. | 2) Only a few casts can be cast at the same time. |

| 3) Patterns are easy to set up on a match plate. | 3) Multiple patterns of large sizes are a bit complicated to set up on the match plate. |

| 4) The small size pattern is attached together with a supporting match plate. | 4) Patterns are split and attached separately on a wooden plate. |

| 5) Solid single patterns are made and attached to match the plate with aligned pins. | 5) Cope and drag sections of the pattern are made separately. |

| 6) Entire assembly of pattern and plate are used at the same time to produce an impression in the mould. | 6) Cope and drag sections of the mould cavity are made separately. |

| 7) Pattern has limitations over the size of the casting produced but not on the numbers/volume of casting. | 7) Pattern has limitations over the volume of the casting produced but not on the size of the casting. |

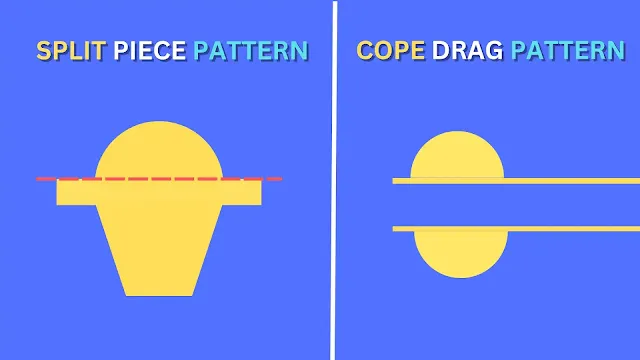

What is the difference between split pattern and cope and drag pattern?

|

| (h) Difference between split piece pattern and cope and drag pattern in casting |

| Split Pattern | Cope and Drag Pattern |

|---|---|

| 1) Split patterns are two-piece patterns which are joined together by an alignment pin. | 1) Patterns here are mounted on a separate flat match plate to produce a cavity in the mould. |

| 2) Small-size casting is produced with this pattern. | 2) Large-size casting is manufactured with this pattern. |

| 3) The cost of pattern production is lower. | 3) The cost of pattern production is higher. |

| 4) The pattern is lighter than the cope and drag pattern and easy to handle in the foundry. | 4) The pattern is heavier than the split pattern and difficult to handle in the foundry. |

| 5) Can only produce more complex shapes than single-piece patterns as there are limitations in pattern making and design as both patterns are aligned by pins. | 5) Can produce more complex and intricate shapes than single and split piece patterns as there is more flexibility in pattern making and design as the pattern is attached to the flat plate directly. |

Cope and Drag Pattern Advantages

- The productivity of pattern making is high as the cope and drag sides of the pattern are made separately.

- Large-size high-quality casting can be manufactured as compared to split patterns.

- Complex and irregular shape casting can be produced using cope and drag patterns as compared to split and solid patterns.

- The pattern is cost-effective for large-size casting if the pattern is made of wood.

- There are fewer limitations and more flexibility in utilizing both sides of moulds.

- Each side of the pattern can be made of different sizes, shapes and designs in cope and drag patterns as compared to solid and spit-piece patterns in casting.

- Tooling cost is low and more inexpensive than the gated pattern and match plate pattern.

- Pattern makers and moulders can focus on each piece separately.

- Best when the casting process is automated.

- The plate used in both the cope and drag sides of the mould ensures proper alignment, and dimensional accuracy and reduces mismatch of both sides of the mould.

- A gating system can be attached through the plates ensuring proper flow of molten metal through channels such as horizontal runners.

- Large-scale moulds can be produced as the process is automated and reduces time and labour costs.

- Plates/frame serves as a reference point for the pattern.

- More than one product can be cast at a time as the plate can accommodate more than one pattern.

Cope and Drag Pattern Disadvantages

- Not suitable for mass production like match plate pattern.

- Not suitable for producing small-size casting.

- It is a labour-intensive pattern-making process.

- These patterns are large patterns and heavy so it becomes necessary to split them into two.

- Handling patterns is inconvenient due to the size of the pattern.

- Two parts of the pattern need to be accurately located on separate match plates to avoid misalignment of the final casting along the parting line.

- Cost, labour, material, and resources required in this pattern is more than in split-piece pattern and single-piece pattern.

- There are limitations to the volume of casting produced, this pattern can produce multiple casting but still volume remains less than the match plate pattern.

- Mould boxes are so heavy that assembly and lifting of the mould boxes become difficult for one operator.

- If plates are aligned improperly chances of mould miss-match increases.

Cope and Drag Pattern Application

Cope and drag pattern is applied in the mechanical, construction, aeronautical, and automobile industry for manufacturing sand casting.

Examples of products and the use of cope and drag patterns to manufacture products are as follows. Aluminium is the most common material used for producing casting.

- Pump housing.

- Compressor housing.

- Turbine housing.

- Flange pipes.

- Crankshaft inserts casting.

- Engine covers.

- Complex shape turbine blades.

- Large engine blocks.

- Pintle socket.

- Water jacket cases.

- Transmission cases.

- Coupling head hose pipes system.

- Manhole covers.

- Machine components.

- Steel components.

Cope and Drag Pattern MCQ (Multiple Choice Question & Answer) / Practice Questions

1) Which pattern from the following is used to manufacture complex large-size high-weight heavy casting?

2) Which of the following statements is correctly related to the cope and drag pattern?

3) Cope and drag pattern makes an impression in which part of the mould?

4) Which of the following statements is true and related to the cope and drag pattern?

5) Cope and drag pattern is the form of?

Cope and Drag Pattern Summary

The cope and drag pattern is one of the patterns among 17 types of pattern in casting.

Cope and drag pattern in sand casting is used to manufacture large-size casting that cannot be manufactured by other patterns such as solid patterns, multi-piece patterns, match plate patterns and split piece patterns.

The cope and drag pattern holds qualities of both split pattern and match plate pattern.

The pattern is split into two but connected by a match plate together to form a single large pattern.